Ronstan OrbitBlock

An award winning, lightweight ratchet block for high performance sailing requirementsCollaboration

Ronstan approached Bayly to assist them in the development of a new ratchet block for high performance sailing that was lighter, stronger and out performed all other offerings on the market. The result was a block that would redefine sailing hardward in terms performance, weight and product longevity through the use of refined engineering solutions and class leading materials.

Process

Working closely with the team at Ronstan, Bayly developed an initial range of concepts that explored a number of revolutionary design solutions in order to meet the outlined performance requirements. The resultant output provided Ronstan with a new way of approaching block development and a means by which the target reduction in weight and increase in performance could be achieved. Through further development and refinement and with the use of class leading materials Ronstan was able to produce a product that significantly reduced bearing stress increasing longevity and has highest working load and lowest product weight in it's class.

Innovation

The Ronstan Orbit Block is now part of an award winning range including taking a Design Mark at the 2008 Australian International Design Awards, a catergory winner at the 2008 Pittman Innovation Awards, the 2008 DAME Design Awards and the 2008 Endeavour Awards and was the 2009 editors choice in Practical Sailor.

Technegas+ Generator

Collaboration

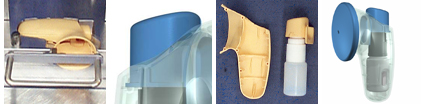

Bayly worked with Vita Medical on the development of the Technegas Plus Generator - a marketing leading device that assists in the diagnosis of pulmonary embolism. Our exterior componentry and trolley development complemented a range of enhancements to software, electronics, hardware configurations and user-interface aspects.

Process

The development process included early conceptual visualisations, detail design and 3D CAD, functional and appearance prototyping and tooling and pre-production management.

The product's construction consists of a combination of thermo-formed Kydex (V0 fire-rated), RTM (Resin-Transfer Moulding), Aluminium die-casting (X-legs), sheetmetal fabrication (trolley) and machined bezels and button components.

Innovation

The Technegas Plus Generator is a modern, more user-friendly and functional device. It has been featured in Australian AntHill magazine (see here), and was shortlisted in the 2007 Australian Design Awards.

For more details on this project, look at our Case Study.

Transdermal Applicator

Developing user-friendly devices for transdermal drug delivery - the realisation of the applicator for Female Hormone Replacement Therapy (HRT)

Cordless Drill

Collaboration

Working with Demain International, a power tool design specialist, Bayly embarked on a project to design and develop the new revolutionary 18V Cordless Drill.

Process

Bayly worked with the team at Demain International to develop concept designs, visualisations, block models and detailed engineering. Bayly was instrumental in the initial development stages and patent-specification of the powered internal chuck - a device that negates the need for external chuck-keys or difficult hand-operated locking mechanisms. Using the power of the motor and a series of gear-selections, the chuck jaws are electronically operated to clasp / release drill bits up to 13mm.

Innovation

This product won an Australian Design Mark for Consumer Products in the 2006 Australian Design Awards. It was also selected to be exhibited at Sydney's Powerhouse Museum as part of the ADA's support and celebration of Australian Design Excellence.

Carpet Display Stand

Collaboration

Teaming with Feltex Carpets and Idea Communications, this project saw the development of a unique and contemporary display stand for Feltex' new Woven range of premium carpets.

Process

Bayly assisted Feltex and Idea Communications in the complete development of CPOD, including initial conceptual development, detail design and 3D CAD, the preparation of photorealistic promotional images, prototyping, tooling and pre-production management.

Innovation

Displaying carpet samples in-store has traditionally been an awkward and space-consuming activity. Given the nature of carpet, its size and bulk, typical display devices did not provide the prospective purchaser with a strong display and demonstration medium.

Typical display units tended to be either a low-profile "water-fall" design, whereby individual carpet samples were layered on top of each other and therefore losing impact, or some retailers invested in expensive and permanent display cases that improved the display of the carpet, but provided no flexibility in store as product lines or interior decor changed

The Feltex Display Stand, "CPOD" was designed with all of the above issues in mind. It presents the carpet samples in a vertical roll, is easily removed and replaced from individual injection-moulded recess modules, and the Octanorm aluminium frame has been developed to maximise in-store flexibility, manuveurability and visual "lightness".

CPOD can be configured to suit the many shapes and sizes of carpet retail stores, the side branding panels are easily removed for cleaning and/or replacement, and the Octanorm overhead lighting provides the most important aspect of point-of-sale display systems - the ability to see the product at its best.

The product was shortlisted for the 2005 Australian Design Award.

Hygiene Plus Total Toilet Cleaner

Invertable Spray Bottle for toilet cleaning

CollaborationBayly partnered with International Consolidated Business to develop an ergonomic spray bottle that allows users to spray a uniqely formulated toilet-cleaning agent in all areas of the toilet. ProcessThe bottle, using a inverted spray-trigger mechanism, can be operated upright and upside-down, enabling users to spray under the toilet rim. This challenging requirement drove the unique shape and configuration of the bottle's design. InnovationWinner of the 2006 Australian Packaging Awards "Packaging for the People" Silver Award. Click here for more information about this award. The product has also been featured extensively on commercial television promotions.

|

Said the judges of the 2006 Australian Packaging Awards"This novel ‘inverted trigger’ design is a great improvement in functionality, effectively alleviating aching wrists from cleaning awkward toilet bowls. Easy to use upside-down and far more comfortable to hold than competitor brands, this winning solution is also a packaging breakthrough.

|

Vlocity Train

Design and manufacture of precision welding and assembly jigs

Collaboration

Bombardier Transportation is the largest train manufacturer in the world. Their manufacturing site in Dandenong Victoria has been refurbished to supply and support 38 VLOCITY trains to the Victorian Government. The VLOCITY train carriage consists of a number of main assemblies constructed from stainless steel frameworks which are assembled and welded together.

Bombardier sought assistance from Bayly for the design, manufacture and supply of the jigs and fixtures used to position and retain this framework during assembly.

Delivering outcomes on time was integral for successful progression of the VLOCITY train project. Prior to the commencement of design work, Bayly worked with Bombardier to develop the budgets and timelines for the design, manufacture and assembly stages.

Process

The design stages of the assembly fixtures were technology based. 3D CAD models of the VLOCITY train carriage were imported from bombardier’s CATIA CAD system into Bayly’s Pro Engineer CAD Tools. The required fixtures were then designed directly onto and around the existing framework.

Aiding Bombardiers visualisation of the working concept,the 3D models also enabled Bombardier to see the steps of design for each fixture and helped them to visualise the assembly procedure. This process saved Bombardier precious time in determining the handling of each item and the choice of welding equipment.

Bayly supported the VLOCITY train project over several months and provided 3D model designs, detailed design, sourced suppliers to manufacture the fixtures and managed the tooling for each assembly fixture. Bayly also managed the commissioning for each assembly fixture. This included the coordination of contract staff to assemble the fixtures and provide dimensional reports that verified the accuracy of the fixtures for Bombardier’s quality requirements.

Innovation

The key feature of Bayly’s design of the assembly fixtures included a simple, cost effective design that reduced manufacturing costs as well as reduced the overall manual labour in assembly.

The design of the jigs met the tight frame tolerances Bombardier required for the train carriages. Bombardier’s original requirement was for one welded fixture per subassembly frame.

Bayly managed to combine various fixtures into the one fixture which saved over $60,000 in manufacturing and assembly costs, as well as overall floor space in their factory.

For more details, look at our Case Study

C-Bus Switchgear Range

Home automation switch interfaces

Collaboration

Our partnershiup with Clipsal Integrated Systems dates back to 1999 when Bayly was asked to provide detailed engineering development assistance in the creation of the Neo keyed C-Bus switch-gear.

Since then, we have been proudly supporting CIS in the development of a range of C-Bus related switches and products, including Neo A-Series (keyed), Neo E-Series (keyed), Saturn A-Series DLT, Saturn E-Series DLT, Neo E-Series DLT and their Colour Touchscreen.

Process

Our major role in this partnership is in developing component and assembly designs around family aesthetic ranges and critical sizing requirements.

Wall-mounted switchgear is governed by many international design and sizing requirements and standards, to enable distribution to international markets. The C-Bus low-voltage switchgear is no exception, and Bayly has helped CIS achieve the family look they require for their products, in addition to squeezing as much hardware and componentry into as small a package as possible.

Our key activities with CIS include conceptual design and assembly configuration development, 3D CAD, 3D CAE, prototyping and tooling / pre-production management of off-shore and local supply partners.

Innovation

Bayly's work has assisted CIS maintain their market-leading position in their industry - reinforcing CBus as an industry standard low-voltage home-automation technology.

Arch Support

Award winning in-shoe support

Collaboration

Working with SSL Australia, Bayly has designed and developed a unique soft gel arch support to aid in the treatment of the symptoms of collapsed arches and to provide shock absorption to the heel area, longitudinal arch and metatarsal areas.

Process

Collapsed arches are a common problem which affect the orientation of the foot relative to the leg. The focus of the design for the new Schroll Arch Supports was on creating a product that can be worn with the more revealing footwear used in today’s world markets and to ensure that users suffering from the pain associated with collapsed arches have adequate support.

The adjustability of the support, is achieved by the clever use of different hardness TPE materials which are colour coded for easy identification. The user simply selects the insert that provides the best result.

Innovation

With its’ unique integrated and adjustable support system, and its clear and clean appearance, the new Scholl gel Arch Support product range has replaced the old brown "mums" range that has been sold by Scholl for many years.

The new product range is available in Small, Medium and Large sizes and can be purchased in Pharmacists and speciality stores throughout Australia, Asia and Europe. The Scholl Arch Supports have won numerous awards including the 2004 Australian Design Award and the 2004 Design Institute of Australia award.

ADG-115 Angle Grinder

Award Winning power tool design

Collaboration

The ground-up development of the ADG-115 Angle Grinder is a result of our great relationship with client Demain International.

Process

To develop, from the ground-up, a revolutionary Angle Grinder with enhanced performance, safety and functional characteristics.

Innovation

Numerous patents have been secured for technologies and systems within the ADG-115. These include recognition of unique electronic functionality, air-thru technology and rotating head design.

The ADG-115 is an international multiple award winner. It took out the 2003 Australian Design Award for consumer products, 2003 Silver IDEA (USA), and 2003 Powerhouse Museum Selection and the 2003 Design Institute of Australia Industrial Design Excellence Award.

Edon Air Fresheners

Contemporary packaging for room-fragrances

Collaboration

Bayly worked with International Consolidated Business to develop a range of gel air fresheners, for the Edon brand. The range includes the "Luna" and "Balance" - patented dual-fragrance air-fresheners

Process

The air fresheners had to exude a unique, artistic or dynamic quality. For example, the "Luna" design is a dual-chamber air freshener that is activated by twisting the two half-round segments and can be adjusted to control fragrance intensity and physical appearance.

The "Balance" design is also a dual-chamber gel air freshener, with independently adjustable fragrance chambers and a distinctive and clean outer aesthetic. Both products were constructed using injection moulded Polypropylene.

Innovation

Consumers can independently control the amount of fragrance released from the dual-chambers, creating the perfect balance and combination of fragrance for the user.

Quadra

Filtered boiling and chilled drinking water system

Collaboration

Billi Integrated Systems asked Bayly to assist them in the development of the Quadra hot / cold water dispensing system that is installed in domestic and commercial environments.

Process

The project included the complete development of conceptual solutions, sub-system configurations and interfaces, above and below bench units, detailed component and assembly specification and 3D CAD, tooling management / liaison and product prototyping and testing.

Innovation

Quadra embodies advancements in energy efficiency, space efficiency and environmental sensitivity. These innovations are in accordance with ESD (Ecological Sustainable Development) and Green Building Design objectives.

Unlike competitor products, Quadra re-uses waste heat generated during the chilling process to assist in water pre-heating - saving substantial amounts of energy. The design also includes enhanced insulation materials and electronic-control systems to ensure efficiency and effectiveness 24/7.

MDN Keyboards

Upgrading Victoria Police Keyboards for robustness, ease of use and reliability

Collaboration

Working with Motorola on the upgrade of the design of computer keyboards, installation and ADR compliance. Motorola required changes to the keyboard and worked with the team at Bayly to improve its robustness, ease of use and reliability.

Process

800 Units requiring modification by NC machining, the addition of internal brackets and the overmoulding of the unit in a urethane with elastomeric properties selected specifically by Bayly for its low cost, UV resistance performance and shock absorbing characteristics. The project required Bayly to design and manufacture special jigs, fixtures and tooling to meet production rates of 50 units per week in Bayly’s workshop and to develop a robust and repeatable process.

Innovation

Motorola were able to get a complete turnkey solution to their problem where the total scope of the project was managed by Bayly. Motorola were also able to build on the investment made in the existing equipment rather than approaching the solution by scrapping and replacing the existing units, this meant a large saving on costs.

10" Frypan

Appearance model of a 10" Stainless Steel Frypan

Collaboration

This model was manufacturered to assist Mistral validate and market their 10" frypan prior to tooling commencement

Process

The model was built using a combination of spun aluminium, heat-formed acrylic, CNC-machined aluminium handles and feet.

The temperature controller was subsequently replaced with the "Genius" electronic controller (pictured bottom-left)

Innovation

This model was used extensively within Mistral's product and management teams to assess the suitability of the product, gain preliminary market acceptance through consumer research processes and to assist in the development of packaging and logistics planning whilst tooling and production occurred.

Funtastic - The Scamble Bug™

A ride on toy that was designed to help children develop balancing, pushing and steering skills

Collaboration

Bayly teamed up with Funtastic and were tasked with designing a new ride-on toy aimed at children moving up from a baby walker product. The toy was required to be steered with just the feet and needed to be easy to manoeuvre and stable.

Process

The Scramble Bug's initial concept development included an in-depth study into the ergonomics of toddlers to ensure it was suitable to all children through this essential transition in their early development. The concepts explored various means by which the unit could relate to young children and inevitably reflected their interest in the weird and natural. Following selection of the concept for development we prepared mock-ups for ergonomic assessment and spacial layout. The toy was then detailed using the latest CAD software taking into special consideration the use of materials required to stand up to the demands of young children. A prototype was produced to assist in proving and testing the the unit while assisting with the refinement of parts and components for tooling.

Innovation

Mainsflush Touch Pad

Collaboration

The success of the Sensorflush development was the result of a close working relationship between Mainsflush and Bayly Group along with software engineers and fabricators.

Process

Following a decision by management to expand their patented touch technology into the prestige market, Bayly were appointed to assist them with the new product development. Identifying the growing trend of engineered stone used within the bathroom provided a clear direction for the products design. Next was the integration of the touch technology into the stone face, the touch sensors, PCB and speaker along with a mounting bracket were all required to fit in a small cavity at the rear of the product whist remaining obscure and unobtrusive. The mounting bracket being the main structural component of the design under went extensive prototyping to ensure it would reflect the products core values of quality and longevity.

Innovation

The Mainsflush Sensorflush won an Australian Design Mark for Housing and Building in the 2010 Australian International Design Awards. The non-porous surface allows for easy cleaning and reduces the potential for germ build-up. The integrated speaker was fitted to provide sensory feedback to the user to notify them of activation of the unit.

Check out the range of Mainsflush products at www.mainsflush.com.au

Washpod 1200

Collaboration

The inspiration and design for the Washpod has been the result of many years of hard work for Fenton Goddard and Alan Ellis. This machine is the result of a number of generations of parts washing machines that have been developed and sold in the local WA market for years. Bayly have joined in the project at the latter stages to resolve various technical issues and to undertake a "design for manufacture" review and implementation program leading up to tooling and manufacture.

Process

Bayly worked with Washpod to refine the design for mass production and to resolve some key performance issues. The design of the Washpod 1200 was documented and controlled through the Arena PLM system, ensuring that the design, management and manufacturing teams based in Perth, Melbourne and China were equipped with the right information at all times. Design changes and control was managed via an engineering change process in the Arena system.

Innovation

As an alternative to the "solvent bath" type cleaning systems that you see at the local mechanics, the Washpod is an Eco-friendly industrial parts washing machine. The product includes an oil/water separation system that cleans the waste water and allows it to be disposed of through ordinary waste water infrastructure. The maintenance procedures for the machine are software controlled and automated. Operation is a simple "push button" process for the operator and requires minimal operator training. The machine comes with a range of handy hand tools and water guns for cleaning difficult spots.

WASHPOD - High Impact Parts Washing

Washpod 1200 is Faster, Cleaner, Safer, Greener

FLATFLAT® is a hydraulic stabilising mechanism that will allow any item with legs, skids or footings to be locked so the legs do not move and the item remains stable irrespective of the unevenness of the supporting surface.

CollaborationBayly worked with the team at FLAT® and with a range of local Australian manufacturers and suppliers to produce the tooling and components that make up the system. Materials selections and testing was a key technical challenge for the system and Bayly's approach allowed for changes in materials to be adapted into the system as required during in service testing. The challenging aspects of the manufacturing process were the assembly of the system components (using ultrasonic welding processes) and the sealing between the different components in the system. ProcessBayly was engaged by FLAT® to industrialize the technology for the first FLAT® product, the FLAT® table application. Using the design developed by FLAT® and e3K as the basis, Bayly undertook detail design, prototyping, tooling supply and commissioning, and the manufacture of pre-production batches for FLAT®. Bayly also developed testing programs and test equipment for the system and its components. InnovationThe FLAT® system increases the functionality, performance and appeal of an array of products as well as reducing ‘level and stability’ warranty costs. Aside from the obvious benefits to the hospitality and furniture industries, FLAT® technology applies equally to domestic and catering appliances, construction, film & TV, defence, medical, in fact any application that requires a stable platform from which to operate. Want to see the system in action? Check it out here. Also check out all the latest news and information on www.flat.net.au |

In May 2010, The FLAT® table levelling system was recognised for it's design and innovation merit with a 2010 Australian International Design Award.

|

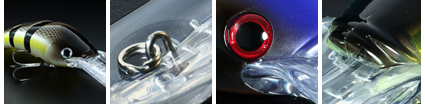

OneWell SUMO fishing lure

Collaboration

OneWell Fishing is a start up company looking to differentiate itself in the market through high quality, high performance products and they engaged Bayly to assist them with achieving this goal. The objective of the new lure was to aim at specific fish species and this demanded a close working relationship between OneWell and Bayly to ensure the lure's optimum performance.

Process

Bayly worked side by side the OneWell team from concept development through to the critial 3D modeling in order to maintain the consistant product aesthetics and performance outlined in the initial brief. With performance being of primary importance, prototypes were used to test various profiles and weight distributions to determine the optimum lure layout and its ability to 'swim' as required.

Innovation

The Sumo range is a first for the One Well Fishing company and exceeded expectations across all areas including product finish, quality and performance.

Check out the full range of lures at www.onewellfishing.com.au

Maxibon Man Chew

Collaboration

Publicis Mojo asked Bayly to work with them to produce a promotional toy for Nestle.

Process

A range of different concepts were generated and considered. The Manchew toy was selected as the best vehcile to use for the marketing campaign. Bayly provided the design of the Manchew to the Chinese manufacturers.

Innovation

If you haven't noticed a visible increase in the number of "chin dominant" males on the streets of Australia then the product has not really done its job. It did however work with the rest of the campaign to produce a reported increase in retail sales of 41%.

In case you missed the essence of the campaign the first time round.......